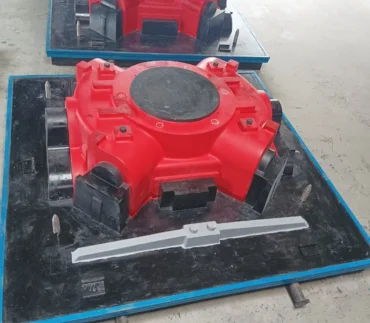

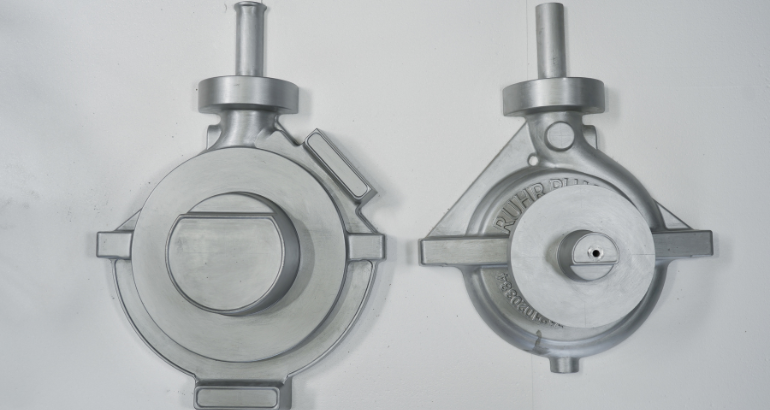

High-Quality Patterns and Castings at Reasonable Prices

Best Industrial Pattern Services in India

We Have

- 40+

- Years

Experience

Our Specialties

Diverse Pattern Materials

Pattern Repair and Maintenance Services

Various Dimensions

Reverse Engineering

CNC Route

VMC Capabilities

Our Products