Machined Components Suppliers for Manufacturing Industries

Company OverviewSangeetha Machining Industries is a leading precision machining manufacturer in Coimbatore, Tamilnadu, India. Sangeetha group of companies was established 35 years ago by Mr. P Rajappa, who has over 40 years of experience in the field of pattern making, Foundry technologies, and machining. Our company offers bespoke components in an extensive range of metals and specific alloys for both industrial and commercial applications.

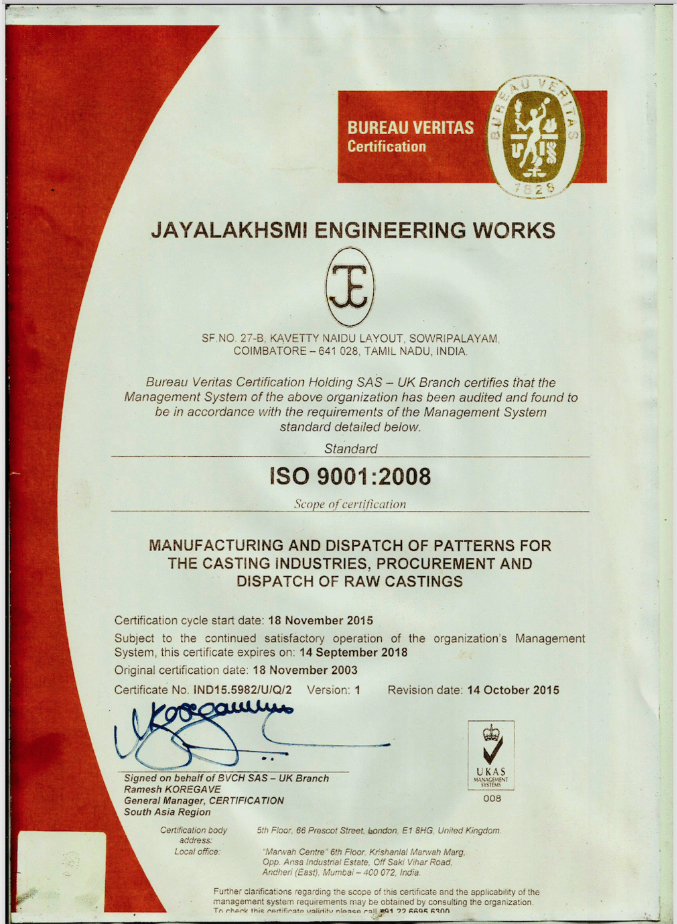

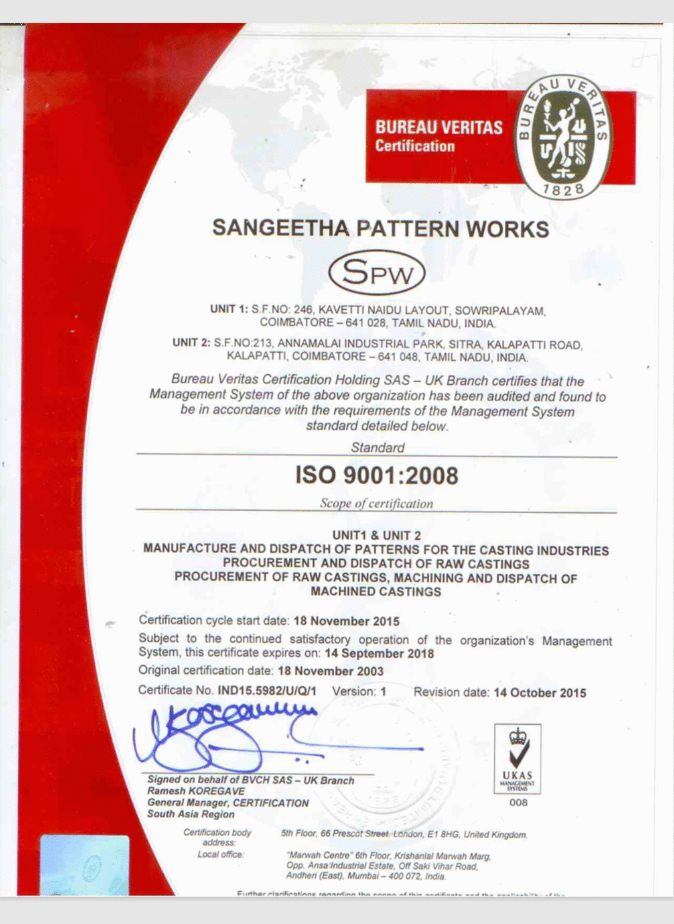

Sangeetha group of companies started business in 1980 in the name of Jayalakshmi Engineering Works, Sangeetha Pattern Works Unit I & II, Sangeetha Machining Industries. We are South Asia's first ISO 9001-2008 certified company by TUV nord India. We are pioneers in manufacturing equipments for various sectors, including automotive components, agri equipments, and the textile industry. We, as a professionally managed business group, have geared ourselves to meet the modern-day challenges with a zeal to work. Currently, the Sangeetha Group of Companies comprises three specialized divisions: Sangeetha Machining Industries, Sangeetha Castings Pvt. Ltd (SCPL), and Sangeetha Pattern Works (SPW). We are actively engaged in the ongoing process of establishing new companies. At the same time, we prioritize forging connections with the world's leading technology companies for plant and equipment within our scope of manufacture. This synergy enabled us to provide tailor-made, cost-effective solutions and the latest equipment to our customers both domestically and internationally.

Why Sangeetha

Machining IndustriesOur company's main objective is to offer our customers a one-stop solution by providing innovative solutions, quality products, excellent service, and a complete manufacturing solution. We offer a wide range of additional services through a friendly and highly experienced team. The company is well positioned to provide its customers with a high-quality product at the most competitive price and excellent on-time delivery performance.

At Sangeetha Machining Industries, Sangeetha Castings Pvt. Ltd (SCPL) and Sangeetha Pattern Works (SPW), we pair tradition with innovation, enabling us to deliver quality machining to our local and global customers efficiently and effectively. Our processes are underpinned by our expertise and experience, as demonstrated through our bespoke 360-degree manufacturing approach, including everything from design to delivery. Sangeetha Machining is capable of tailor machining according to your requirements, whether it is a small, high-value run or a bulk mainstream run. With state-of-the-art foundries and a focus on casting expertise, Sangeetha Castings Pvt. Ltd provides durable, reliable, and precisely engineered castings that form the backbone of countless products and processes. At Sangeetha Pattern Works (SPW), we understand that patterns are the cornerstone of successful manufacturing, and our commitment to perfection is reflected in every piece we create. Please take a tour through our website to discover what we can offer and why you should come to Sangeetha Group of companies for all your requirements. Our skilled team would happily engage in project discussions and provide you with a competitive quotation, ensuring your projects are in capable hands.

Our comprehensive in-house end-to-end service covers everything from design and tooling to rapid prototyping, casting, and machining. This approach enables us to have complete control throughout the manufacturing processes.

Our in-house design facility eliminates the additional cost of engaging a third-party design house. Moreover, it provides us the added comfort of complete control over the quality and integrity of the design stage.

The production of tooling & machining in-house is a fundamental component of our end-to-end service, enabling speedy and smooth changes while simultaneously reducing both time and costs. Our state-of-the-art in-house tool room is equipped with the most up-to-date software and CNC machinery.

We provide customers with a comprehensive end-to-end, one-stop service, cutting down on time scales and offering complete traceability throughout the manufacturing process.

Processing System

Processing SystemSangeetha’s experienced workforce is guided by a process-oriented approach to execution in every part of the organization. This process-oriented approach has enabled us to embrace a holistic approach to managing precision. Our commitment to process-driven precision begins with ISO 9001-2008 certified and compliant processes, spanning from contract review to various aspects, including risk management, project management, and continuous improvement. We have embraced a process-oriented approach in developing, implementing, and enhancing our management system, ensuring effectiveness at every stage. We leverage the application of knowledge, skills, tools, techniques, and systems to effectively manage and improve our processes with the goal of exceeding your expectations. We consistently evaluate health and safety risks and implement control measures and systems to reduce these risks effectively.

Our comprehensive in-house end-to-end service at Sangeetha Machining Industries, Sangeetha Castings Pvt. Ltd (SCPL) and Sangeetha Pattern Works (SPW) gives us full quality control throughout the design stage and manufacturing processes. We integrate our own in-house Design and tooling facility, rapid prototyping, machining, and finishing capabilities. We use the latest manufacturing techniques with vigilant monitoring for excellence at every stage of the process. Sangeetha Group of Companies delivers precision machining and manufacturing services across various engineering sectors from its factory in Coimbatore, India.

Facilities

Facilities

- ISO 9001 certified

- Quality level of 99.99%

- Wide-ranging customer base

- Prototype, batch, and volume production

- 80+ experienced labourers are working in our concern

- We offer CMM reports for each machined casting

- We use licensed Solid Works software for 3D Design

- We have a dedicated in-house unit for pattern making, casting, and machining

- We provide good castings to our customers, accompanied by test certificates for assurance

- Dedicated and passionate management, along with a highly skilled workforce, actively fuels the growth of our business through continuous development.

- Well-conditioned machines like Conventional lathes, CNC turning center, CNC vertical turning lathes (VTL), CNC vertical machining center (VMC) with 4th axis, Radial drilling, Milling machines, Drilling machines, Surface grinding & burnishing